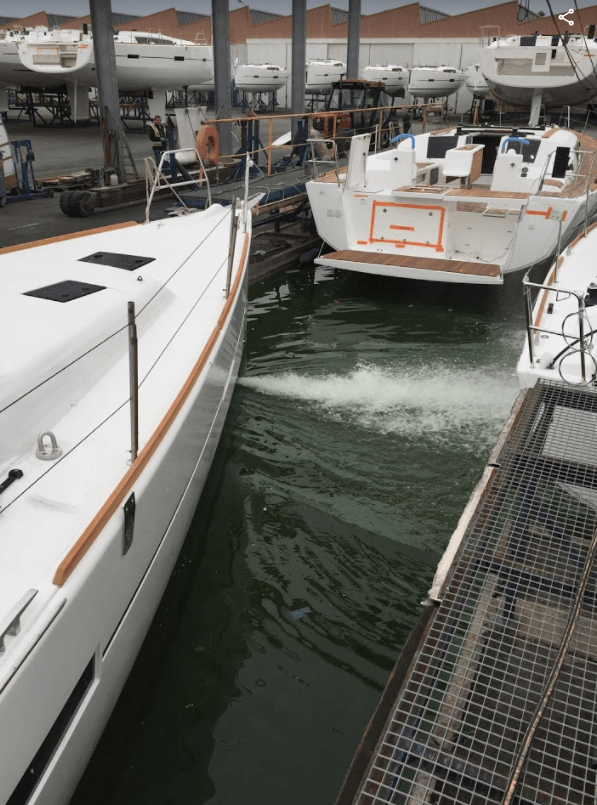

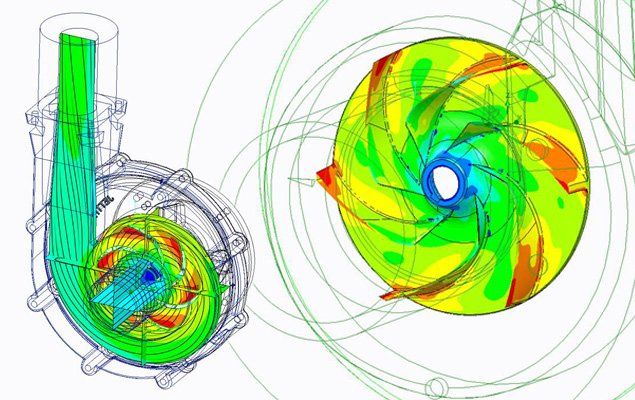

Jet Thruster makes use of a high power electrical Turbine style Centrifugal water pump. You can use the system as Bow Thruster, Stern Thruster, or in combination to make the full "docking system" Jet Thruster, a unique product in the industry.

The system works like any other boat thruster: Push the joystick or button to port or starboard, and the boat will move in that direction.

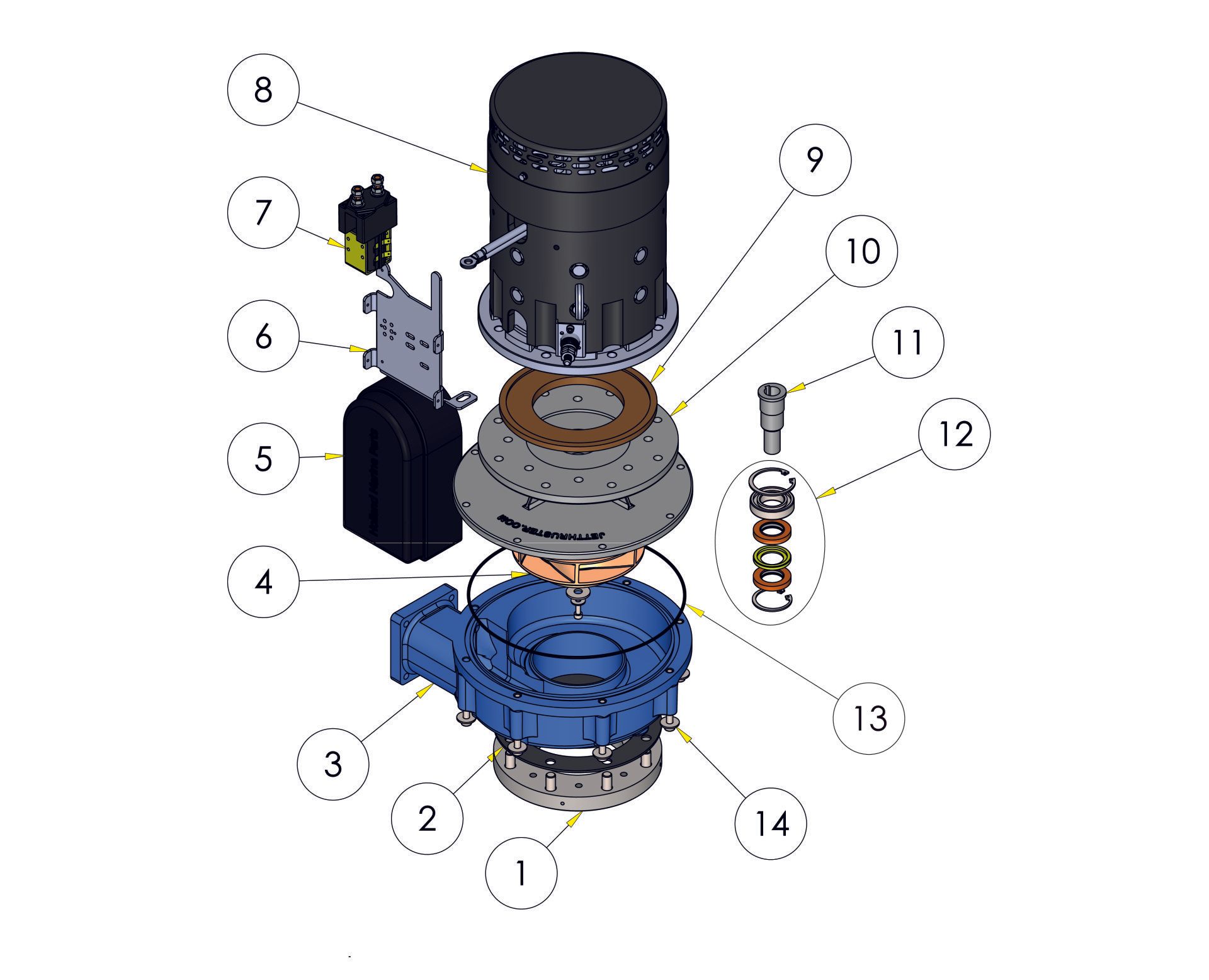

All parts of the system are made from high quality Stainless Steel 316 or High grade Composite materials, and are certified to meet industrial quality standards.

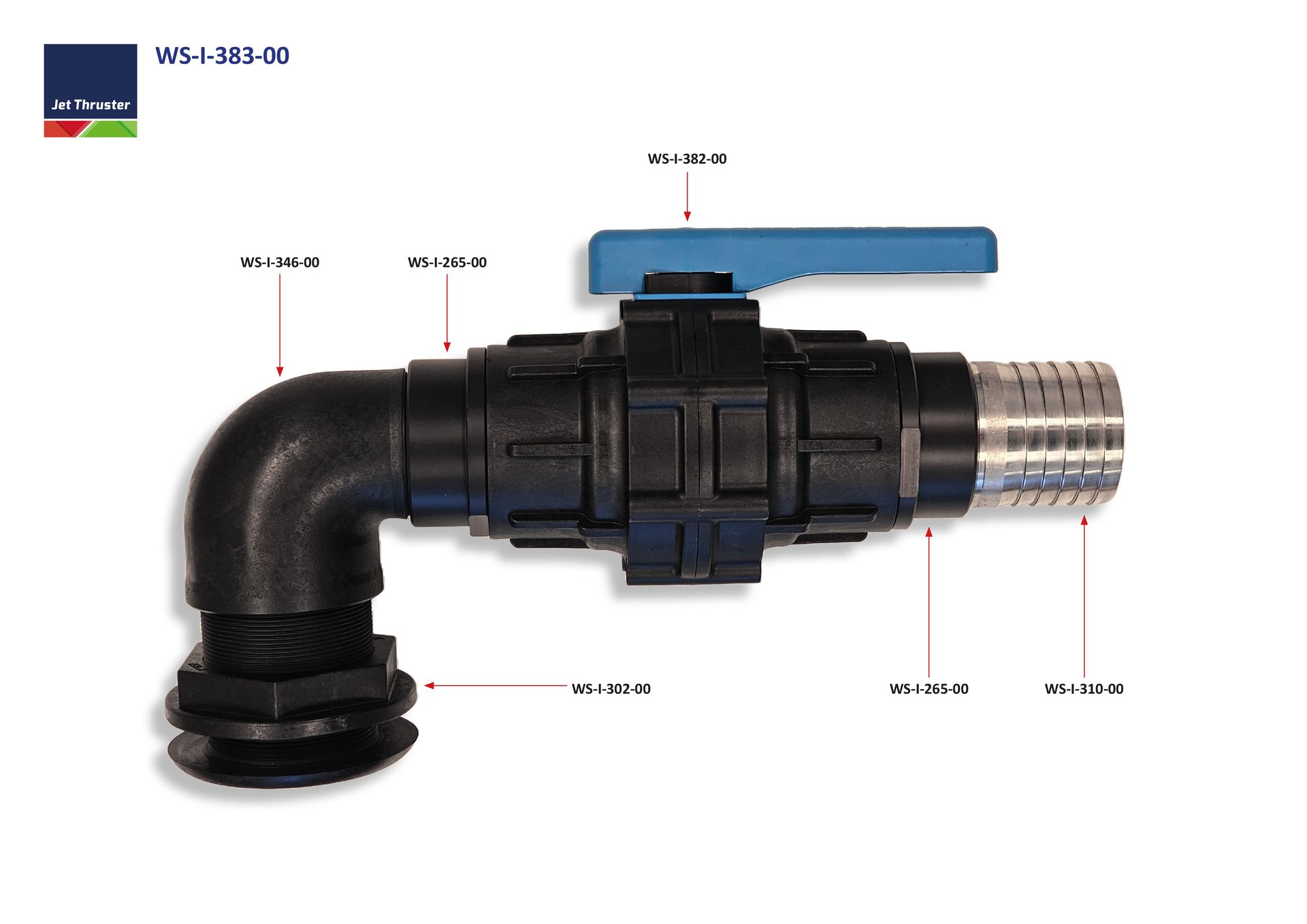

The Jet Thruster pump draws water thru a 3" or 4" intake on the bottom of the boat, fitted with an isolation ball valve. The powerful pump generates a large water flow, directed thru flexible reinforced rubber hoses by proprietary electro-motive valves. The system works on the principal of low pressure and high flow rate.

The water flow is directed to nozzles which are located Forward and Aft in the boat, just below the water line. From this nozzle the water jet will exit the nozzle, and push the boat into the direction of choice. The size of the outlet nozzles allow for placement at the extreme ends of the bow and stern, maximising efficiency.

Without the need for specialized fiberglassing, any skilled or DIY technician can install the Jet Thruster in virtually any pleasure yacht on the market.

With four models of Jet Thruster, our systems are normally installed to 25-60Ft yachts, but can be scaled to virtually any size vessel.